KIm Kwang-nam, CEO of HMT Co., Ltd.

Under the motto of the best product, the best quality Through continuous R&D, quality control activities and automation facilities, It has emerged as a competitive company in terms of price.

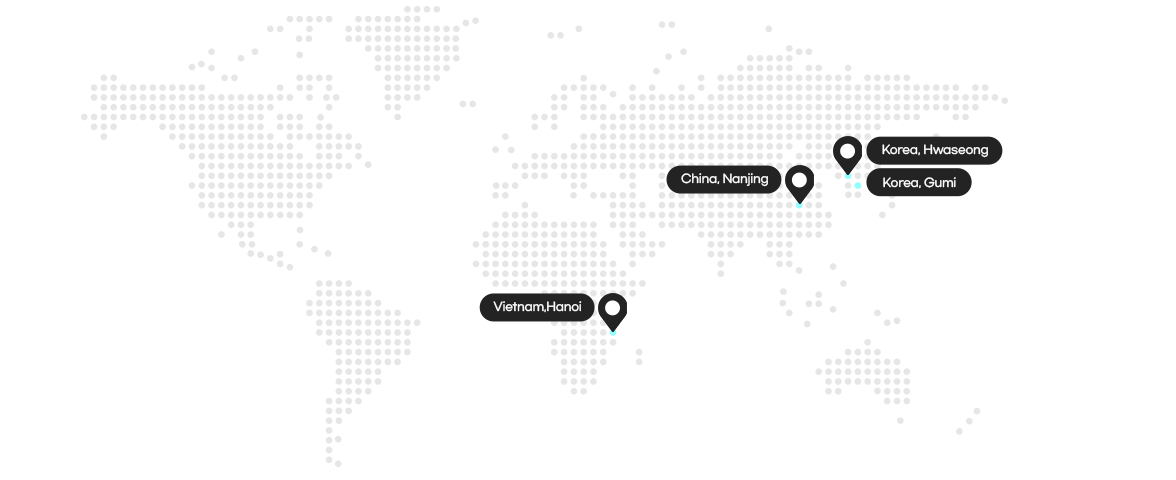

▲ NANJING MIRAE Electronics

▲ NANJING MIRAE Electronics

1491, Beodeul-ro, Paltan-myeon, Hwaseong, Gyeonggi-do

1491, Beodeul-ro, Paltan-myeon, Hwaseong, Gyeonggi-do

NO.5 Tengying South Road Hengliang Town Liuhe Zone Nanjing China

NO.5 Tengying South Road Hengliang Town Liuhe Zone Nanjing China

Workshop G6.1, East Zone of Phu Thai Industrial Park, Kim Luong ward, Kim Thanh District, Hai Duong Province, Vietnam

Workshop G6.1, East Zone of Phu Thai Industrial Park, Kim Luong ward, Kim Thanh District, Hai Duong Province, Vietnam

HMT Co., Ltd. is working hard to fulfill its vision of ‘a Global Leader in Customer-Oriented Quality’

and aims at perfect quality through assessment of process-specific quality risks and creation / revision of work standards.

- Development, layout

- Checking, customer, requirements

- Customer, layout and product

- specifications

- Development, plan & schedule(development, request)

- Designing and realizing, molds by molding, companies

- Reviewing and procuring fabrics, meeting customer requirements by fabric suppliers

- Reviewing previous material properties(through outsourcing)

- Developing new material properties

- Checking realization of molds

- Checking specifications of fabrics

- Checking prototype as against customer layout

- Final inspection

- Approval for mass-production of an item

- Completion of production

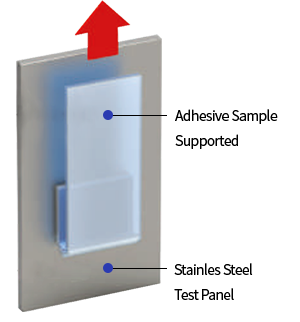

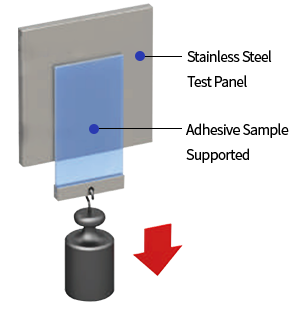

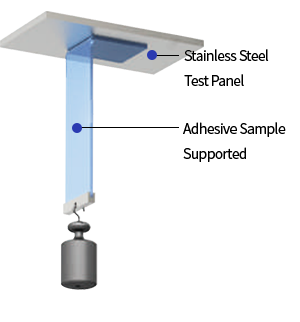

Through testing adhesive power, maintaining power, static load, top-bottom resistance, horizontal resistance and resistance of adhesive surface, we share value with customers to create new value and therewith strive to provide products with good quality and at a reasonable price.

Adhesive power test

Holding Power 180˚

Measurement of maintaining power

Holding Power 90˚

Measurement of static load

Holding Power 90˚

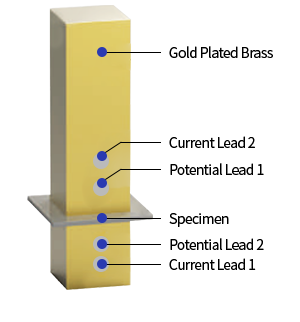

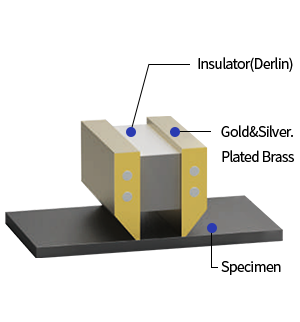

Top-Bottom Resistance

Top-Bottom Resistance

Horizontal resistance

Holding Power 180˚

Present you with the advanced technology of the future

01. Roll Cutter

02. Ball Trck Tesker

03. Electron Microscopy

04. Cutting Protter

05. Low Resistance Meter

06. Motorized Tape Roller

07. Natural Convention Oven

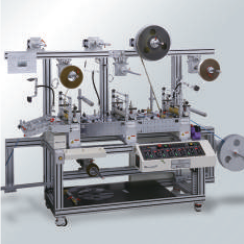

08. A/T High Speed Die-Cut Machine

09. Auto Laminator

10. Temperature & Humidity Chamber

11. Holding Power Timer Parts

12. Sensor Cutter

13. Peel Adhesion Strength Tester

14. Rotary machine

15. PE FILM Press

16. Bag Processing Equipment

We provide living solutions for a prosperous future.

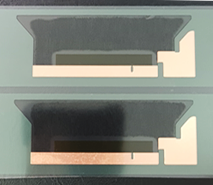

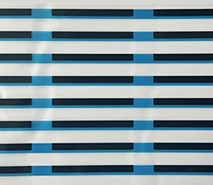

Light-screening tape is a specially manufactured double-sided tape with a thickness of 30㎛ to 220㎛ that boasts anti-abrasive, anti-chemical, and greatly adhesive as well as optical properties. The black side of the functional tape registers a high level of light-screening and covering, while its white side has a high level of reflectivity. The product serves to prevent loss of light beyond lighted area, while additionally seving to fix LCD

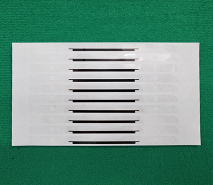

The half-hardened tape is manufactured by first steeping heat-resistant in plastic integrated maca and then gluing to it reinforcing materials such as glass sheet, polyester film, and non-woven fabrics

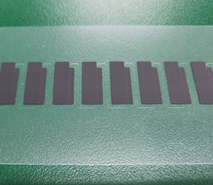

PET is insulating material with excellent mechanical strength and abrasion-resistance that is used in various areas including electrical engineering and electronics

Polyester tape with godd heat-resistance that registers excellent solvent-resistance and superb chemical resistance

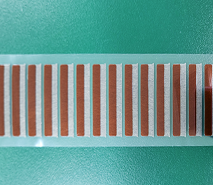

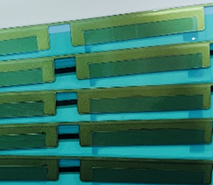

onductive adhesive tape is essential for the handling ofelectromagnetic waves generated by various IT products. Its raw materials include a variety of conductive textiles and metals, while conductive acryl is used as adhesive substance. Characterized by machinability and flexibility the product registers a high rate of conductivity, excellent EMI shidlding, and superb adhesion. The lineup includes a flame-resistant conductive adhesive tape(halogen-free) and 11 UL-certified products.

It server to reflect light coming out of the underside of light guide panel and return it into the panel.

Located on top of laght guide panel the product serves to diffuse light advancing from th surface of the light guide panel in a certain direction to let it spread evenly across the panel surface.

The product elevates brightness on the backlight surface by refracting and converging light that comes off the diffuser sheet

It uses the transparent acrylic panel to receive light diffused from the lamp And then with the pattern with certain size and shape t hat is coated of the acrylic surface the product serves to spread light evenly across the screen

We provide living solutions for a prosperous future

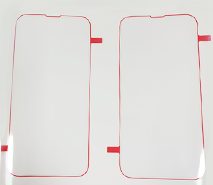

1. PROTECT FILM

2. FOAM TAPE

3. GASKET TAPE

4. SUS PLATE

5. CUSHION TAPE

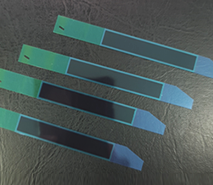

1. CAMERA HOLE A TAPE

for fixing PCB

2. EMI TAPE

3. GAP FILLING TAPE

1. INSULATION SHEET

2. PULL TAPE

3. COVER SHILED

4. SINGLE SIDE TAPE

5. SINGLE SIDE TAPE

6. COVER SHIELD

7. COG TAPE

8. PE-BAG

9. AL-BAG

1. INSULATION SHEET

2. PULL TAPE

1. ITO TAPE

2. COG TAPE

3. LB TAPE

4. Protect Film

HMT Co., Ltd in implemented through organic collaboration among working-level departments in business, community, and environment in accordance tith the company’s medium-and-long-term vision.

With innovative products developed through new materialsand improved processes we willdemonstrate our corporate vision for opening up the future.

A transparent companythat shares growth withcustomers by listening to their voices.

The company will do its best in improving manufacturingand work process in the way of cherishingand respecting environment as a community member.

While working hard to discover future growth engines through continued investment in R&D, HMT promises a vibrant future as a global company by acquiring various thchnological certifications.

Will work hard to efficiently manage risks throughforecasting future business environment and developing future technology with a challengingspirit that doesn’t choose to settle for status quo.

In order to create future value, the best human resources and Through continuous quality improvement based on accumulated technology. We want to realize customer satisfaction based on customer trust.